FOXWELL Car Battery Load Tester for 12V 24V Cranking and Charging Start-Stop System Test Tool BT780 Auto Batteries Analyzer with Built-in Thermal Printer

Retail Price:

$

299.99

Wholesale Price:

Inquire Now

This website follows the safe harbor principle. If any infringement, please inform us in time

and we will delete it in time.

About safe harbor,please click here to learn more.

After Sale Service:

1 Insurance Policy:

Click to go to the Help Center to view the Insurance Policy

2 The rules apply and summit for receive compensation

3 The conditions of accrual for amount insurance

3 The conditions of accrual for amount insurance

5 Damage to the parcel during international shipping, which resulted in damage to the goods in it

6 Loss of individual goods under international shipment

The absence individual goods in the parcel

7 Non-compliance individual goods in color, size, complications

Damage to the goods during international shipment

8 Returns Policy:

Click to go to the Help Center to view the Returns Policy

FOXWELL Car Battery Load Tester for 12V 24V Cranking and Charging Start-Stop System Test Tool BT780 Auto Batteries Analyzer with Built-in Thermal Printer

FOXWELL Car Battery Load Tester for 12V 24V Cranking and Charging Start-Stop System Test Tool BT780 Auto Batteries Analyzer with Built-in Thermal Printer

BEST SELLERS

Product Description

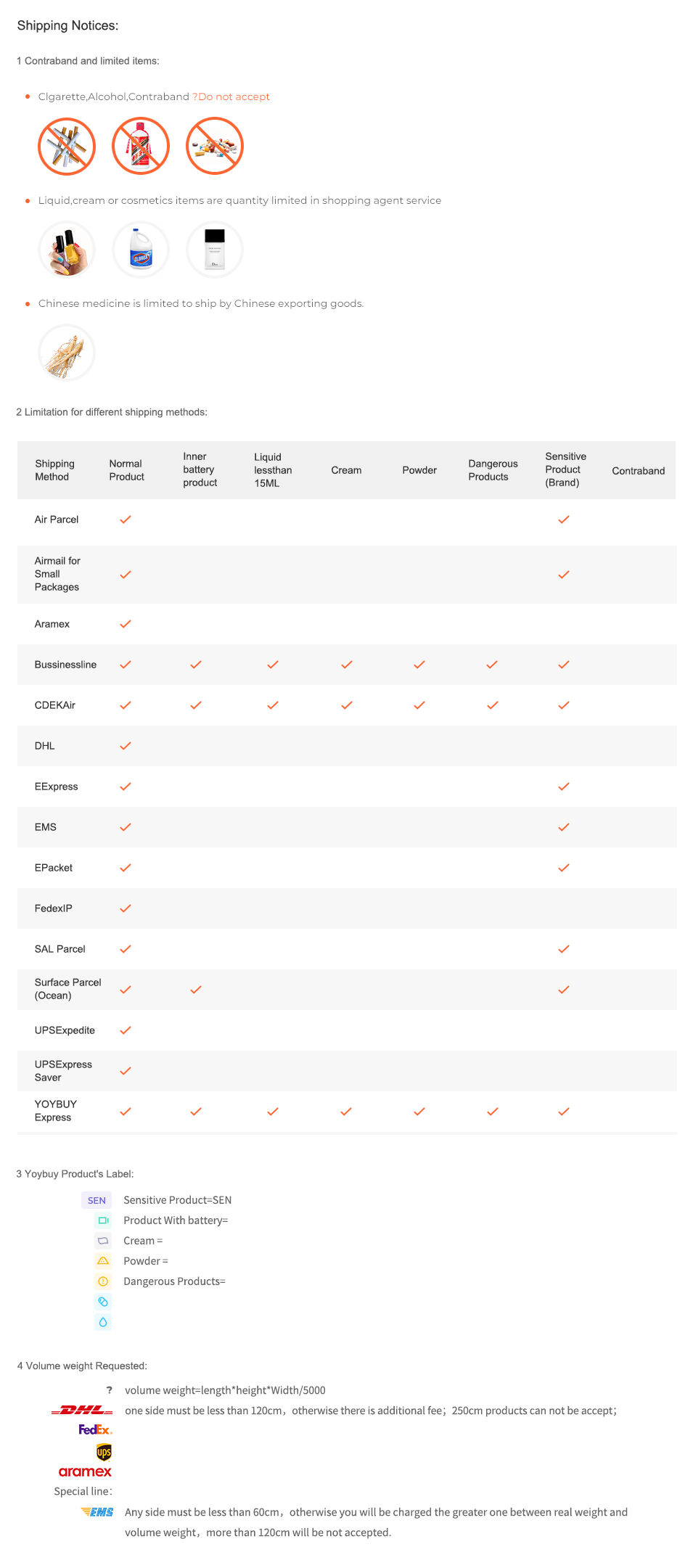

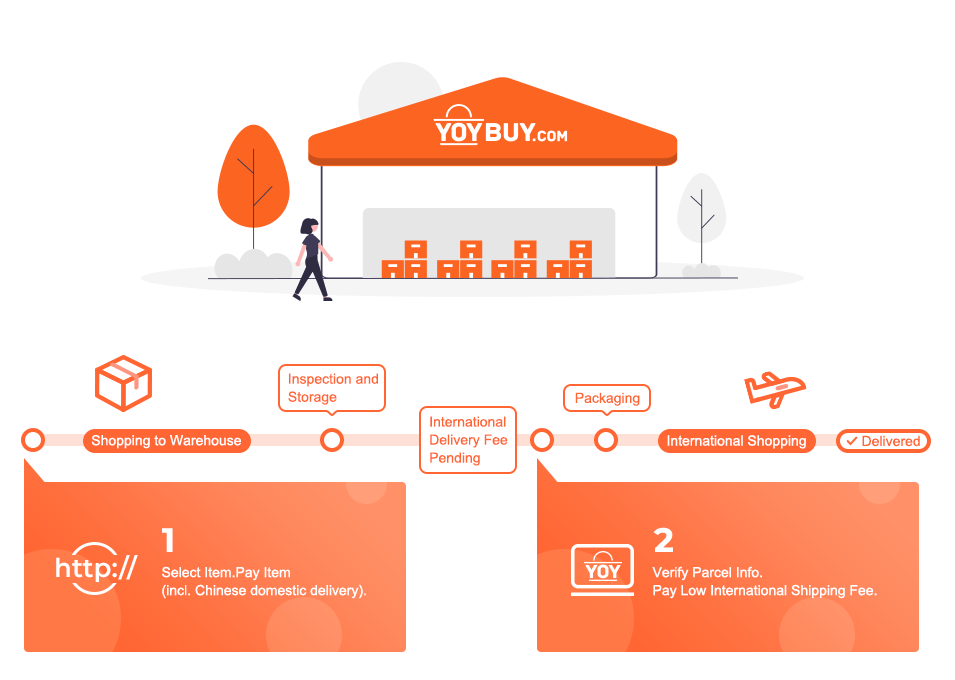

Shipping Notices:

1 Contraband and limited items:

Clgarette,Alcohol,Contraband ?Do not accept

Liquid,cream or cosmetics items are quantity limited in shopping agent service

Chinese medicine is limited to ship by Chinese exporting goods.

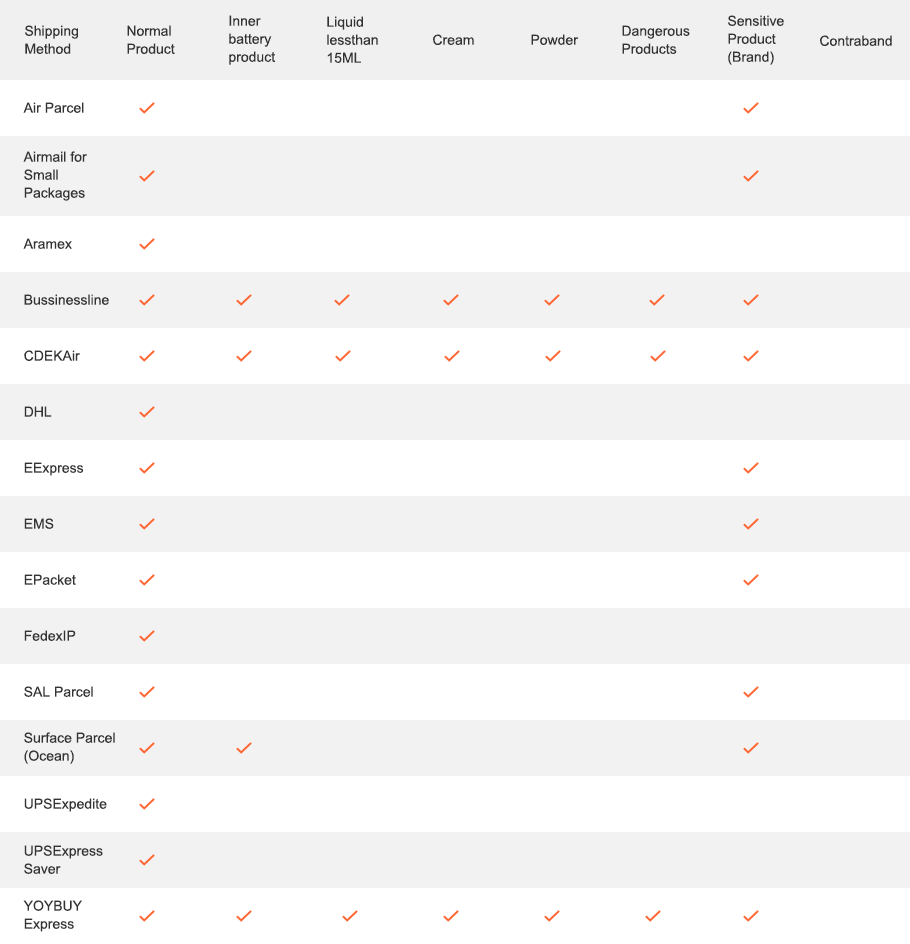

2 Limitation for different shipping methods:

3 Yoybuy Product's Label:

Sensitive Product(SEN)

Product With battery

Cream

Powder

Dangerous Products

4 Volume weight Requested:

volume weight=length*height*Width/5000

one side must be less than 120cm,otherwise there is additional fee;250cm products can not be accept;

Any side must be less than 60cm,otherwise you will be charged the greater one between real weight and volume weight,more than 120cm will be not accepted.

After Sale Service:

1 Insurance Policy: Click to go to the Help Center to view the Insurance Policy

2 The rules apply and summit for receive compensation

3 The conditions of accrual for amount insurance

3 The conditions of accrual for amount insurance

5 Damage to the parcel during international shipping, which resulted in damage to the goods in it

6 Loss of individual goods under international shipment

The absence individual goods in the parcel

7 Non-compliance individual goods in color, size, complications

Damage to the goods during international shipment

8 Returns Policy: Click to go to the Help Center to view the Returns Policy

BEST SELLERS

Language

Language

Currency

Currency

Upload image to find the same item

Drag the image here, or

Click to upload

Tips: Only jpg, jpeg, png, webp

Drag the image here, or

Click to upload

Tips: Only jpg, jpeg, png, webp

Scan the QR code and use your phone to take a direct photo search.

×